Understanding downdraft tables

What is a downdraft table?

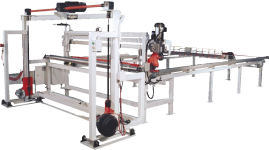

Downdraft tables are specialized workstations designed to remove airborne dust caused by woodworking. The table itself incorporates a powerful ventilation system, using downward airflow to effectively capture and control dust, fumes and other particles effectively.

How do they work?

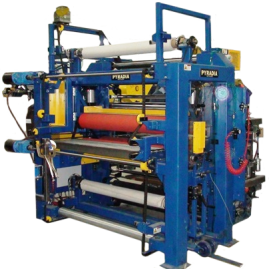

The operating mechanism of downdraft tables involves several key elements:

• The work surface, i.e. the area where carpentry tasks are performed.

• The exhaust system creates a negative pressure area, drawing dust and contaminants downwards.

• Filters trap airborne particles. Downdraft tables come with several filter types to meet different needs.

• The fan/blower powers the system and ensures efficient airflow for dust collection.

• The clean air return circulates filtered air back into the workspace.

The importance of dust management in woodworking

Wood dust is not just a nuisance; it is a health hazard. Fine particles can cause respiratory problems and aggravate illnesses such as asthma.

Moreover, wood dust can present a fire hazard if not properly controlled. Downdraft tables are crucial to creating a safer, healthier working environment by effectively capturing wood dust at its source.

The many advantages of downdraft tables

1. Improved worker safety: downdraft tables considerably reduce health risks by effectively capturing wood dust.

2. Increased productivity: a cleaner working environment means less disruption and more efficient operations.

3. Equipment protection: dust can damage machines over time. Downdraft tables help extend the life of equipment by keeping it clean.

4. Regulatory compliance: many regions have strict workplace air quality guidelines. Downdraft tables help meet these standards.

5. Improved part quality: dust-free environments lead to better finishes and quality products.

6. Versatility: the tables are suitable for a variety of woodworking functions, from sanding to cutting.

7. Environmental responsibility: effective dust management contributes to a healthier overall environment.

Making an informed choice

Consider the size of your workspace, the types of projects you complete and the specific requirements of your operations when selecting a downdraft table for your woodworking needs.

Look for tables with adjustable features to optimize airflow and efficiency for a variety of tasks.

A complementary and necessary tool

A downdraft table is not just another tool in the woodworker’s arsenal; it is an investment in health, quality and efficiency.

It creates a safer, cleaner and more productive environment by effectively controlling woodworking dust, benefiting both workers and businesses.

Follow us on Linkedin and Twitter!