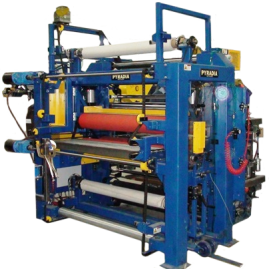

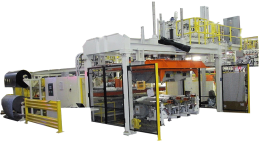

most versatile and compact series of automatic turret winders

Details

TURRET WINDER OPTIONS

All of our models, from the simplest single position stand to the most sophisticated automatic turret can incorporate the following features and options:

CONSTRUCTION TYPES

- Heavy-walled fabricated tubular structure

- Thick machined plate construction

TENSION CONTROL

- Manual tension control

- Ultrasonic diameter sensing

- Dancer-roll control

- Closed loop transducer roll control

SPLICING / CUT & TRANSFER

- Optional operator-assist-splice-table, incorporating up- stream & down-stream pneumatic web clamps, a knife guide and a tape dispenser

- Manual splice, semi-automatic and fully automatic flying splice capability for our single, two position and turret unwinds

- Manual, semi-automatic and fully automatic cut &transfer for our single position, turret and linear displacement winders

- Zero speed unwinds lap/butt splice

BRAKES / DRIVES

- Pneumatic puck style brakes

- Magnetic particle braking techniques

- AC Vector drives for very low tension

- Servo drives

- Fully reversible systems

- Braked or driven

Center, surface or surface/center driven

OTHER AVAILABLE FEATURES

- Over/under unwind/wind capability

- Manual side-lay, automatic edge guiding, centerline guiding

- Skew roll for baggy edges

- Shafted or shaftless

- Cantilevered or removable mandrel

PERFORMANCE SPECIFICATIONS

STANDARD DESIGNS* :

| MODEL – TURRET WINDER | MAX ROLL DIAMETER (A) | MAX ROLL WEIGHT | MAX WEB WIDTH | MAX SPEED |

| TREW 40 | 40’’ | 3500 lbs | 84’’ (2100 mm) |

|

| (1000 mm) | (1600 kg) | |||

| TREW 48 | 48’’ | 5900 lbs | ||

| (1200 mm) | (2700 kg) | 2000 fpm (600 mpm) |

||

| TREW 60 | 60’’ | 10000 lbs | ||

| (1500 mm) | (4500 kg) | |||

| * Pyradia is a manufacturer of tailored engineered web converting equipment. If the characteristics of your projects fall outside the above standard specifications, our engineering team has the expertise to re-engineered existing and standard designs of turret winders and provide an affordable custom-made solution answering your needs. | ||||

MACHINE ACCESSORIES:

- Slitting knives

- Shaft and Roll handling

- Pneumo-hydraulic guiding system.