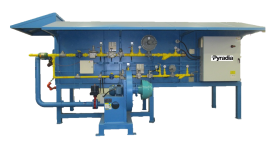

Accurate temperature and pressure control

Details

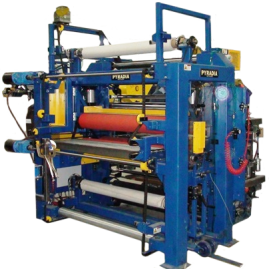

HOTMELT PANEL LAMINATOR

We have recently introduced a state-of-the-art, continuous roller panel laminating system. This laminator is ideal for the application of various hot melts such as EVA, PSA, PUR, APAO, etc.

HOTMELT PANEL LAMINATOR FEATURES:

- Flow-through continuous press

- Flexible design that integrates multiple slot die configurations

- Quick change-over times between rolls

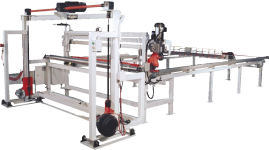

- Manual or optional automatic laminate threading system

- Fast and easy setup changes between lamination force and panel gap adjustments

PERFORMANCE SPECIFICATIONS:

- Feed speed: 10-100 FPM (3-30 m/min)

- Gap adjustment: ½’’ to 4’’ (12.7 – 102 mm)

- Nip pressure: 20-100 PLI (357 – 1786 Kg/m)

MACHINE ACCESSORIES:

- Coating head, slot die bracket and glue melter

- Bowed rolls

- Spreader rolls

- Skew rolls

- Infeed/Outfeed Conveyors

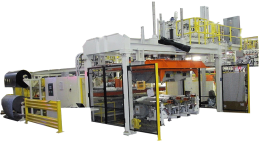

FIELDS OF APPLICATION:

- Veneered wooden panels

- Acoustical panels

- Architectural wall panel manufacturing

- Office partitions

- Insulation panels

- RV

TECHNICAL DATA:

| HOTMELT PANEL LAMINATOR MODEL | A | B |

| PLM 54 | 54’’ (1372 mm) | 110’’ (2794 mm) |

| PLM 68 | 68’’ (1727 mm) | 124’’ (3150 mm) |

Custom lamination systems are also offered.