AMS2750E & Nadcap compliant

Pyradia

>

Industrial ovens & furnaces

>

Products

>

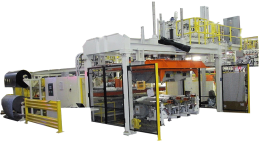

Aluminum solution heat treating – Drop bottom ovens

Details

Heat treating furnaces applications:

- Heat treatment of aluminum parts

- T4 and T6 aluminum solution heat treating

- Aging heat treating processes

Features

- AMS2750E & Nadcap compliant

- Temperature uniformity of +/- 9oF (5oC) at any temperature, from 300oF to 1 200oF (150oC to 650oC)

- Choice of quench time in less than 5,7,10 ou 15s

- Fastest ramp-up and lowest consumption

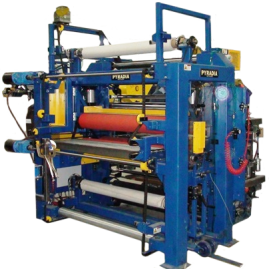

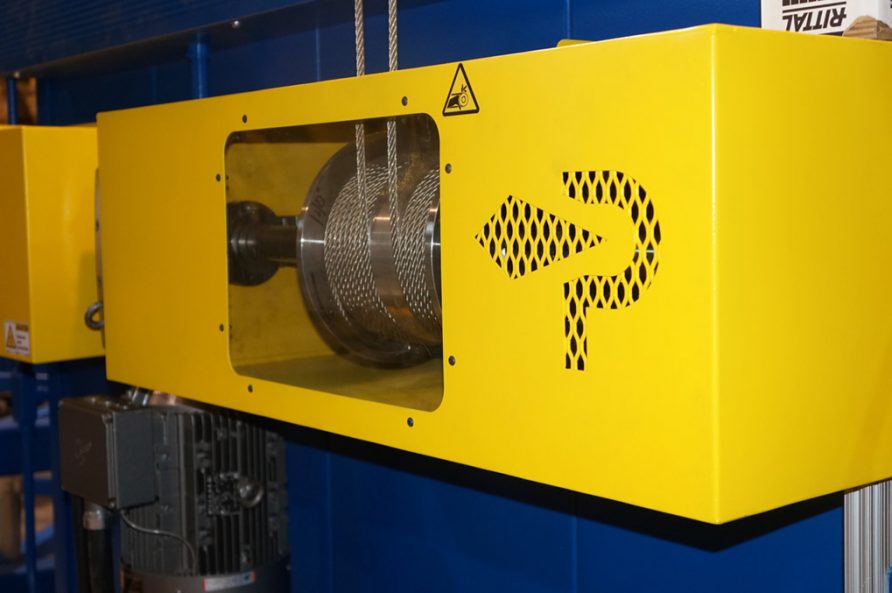

- Dual speed electro-mechanical winch system simple and reliable

- Electric or gas heating

- Ceramic fiber block module insulation

- Stainless steel air baffle

- Sliding or swinging door

- High volume recirculating stainless steel fan

- Pneumatically operated doors

- Tank mounted on a mobile cart with rails

- Heating elements and belt driven circulating fan mounted in protected chambers beside and above the working area

- Load capacity up to 2 000 lbs (900 kgs) for standard models

Options

- Temperature uniformity de +/- 3oC (±5oF)

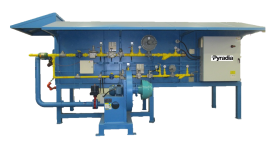

- Quenching tanks cooling system

- Quenching tanks heating system

- Quenching tanks insulation

- Safety curtain

- Glycol management system enabling water/glycol separation for regulating the concentration of the solution and recuperation

- Sand filtration/recuperation system

- Mezzanine for operating station

- Rinse tank(s)

- Additional quench tank(s)

ELECTRICDROP BOTTOM OVENS |

WORK ZONE

DIMENSIONS |

||

| Models | Width | Length | Height |

| (in / cm) | (in / cm) | (in / cm) | |

| EDQ 036036042 | 36 / 91 | 36 / 91 | 42 / 106 |

| EDQ 048048048 | 48 / 121 | 48 / 121 | 48 / 121 |

| EDQ 048072048 | 48 / 121 | 72 / 182 | 48 / 121 |

| EDQ 048096060 | 48 / 121 | 96 / 244 | 60 / 152 |

| EDQ 060060060 | 60 / 152 | 60 / 152 | 60 / 152 |

| EDQ 060080060 | 60 / 152 | 78 / 200 | 60 / 152 |

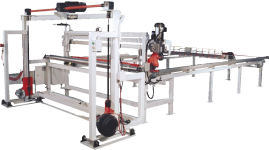

Additional sizes of drop bottom furnaces (for the treatment of aluminum cladding):

| WORK ZONE

DIMENSIONS |

|||

| Models | Width | Length | Height |

| (in / cm) | (in / cm) | (in / cm) | |

| EDQ 048108060 | 48 / 120 | 108 / 275 | 60 / 152 |

| EDQ 048132060 | 48 / 120 | 132 / 335 | 60 / 152 |

| EDQ 048132072 | 48 / 120 | 132 / 335 | 72/ 180 |

| EDQ 048156060 | 48 / 120 | 156 / 396 | 60 / 152 |

| EDQ 048156072 | 48 / 120 | 156 / 396 | 72 / 180 |

Gas Drop bottom furnaces:

please contact us for further information.

Most popular hoist design selections:

| Parts + Basket capacity: | 500 lbs (226kg) | 1000 lbs (454 kg) | 2000 lbs (907 kg) |

| Quenching Time (s) : | 5, 7, 10, 15 |

| * The above models are our most popular sizes, other sizes available on request. |

| * PYRADIA is continuously improving their product lines. Specifications may change without notice. |