Flatbed laminators

Details

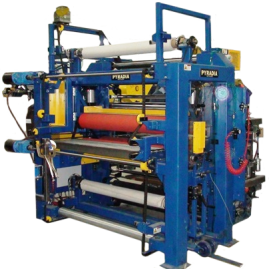

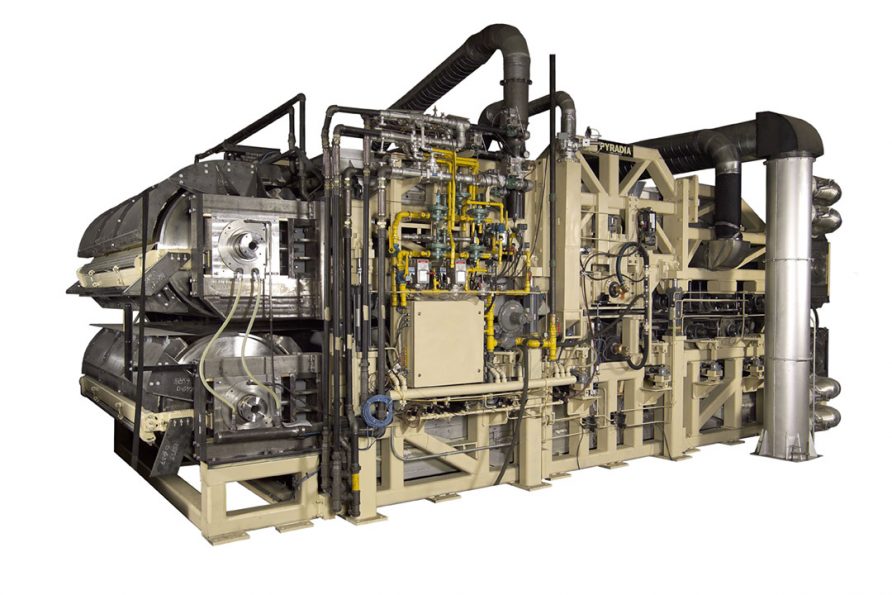

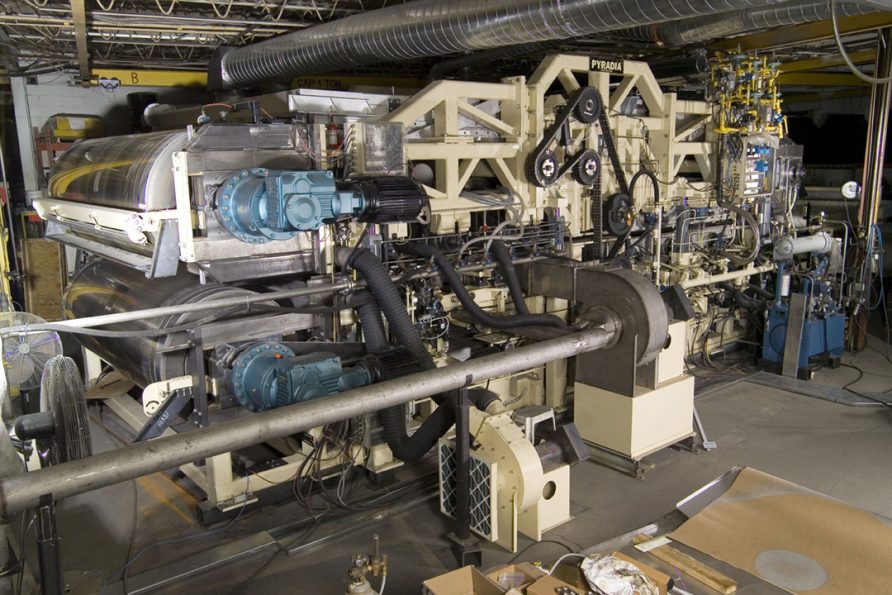

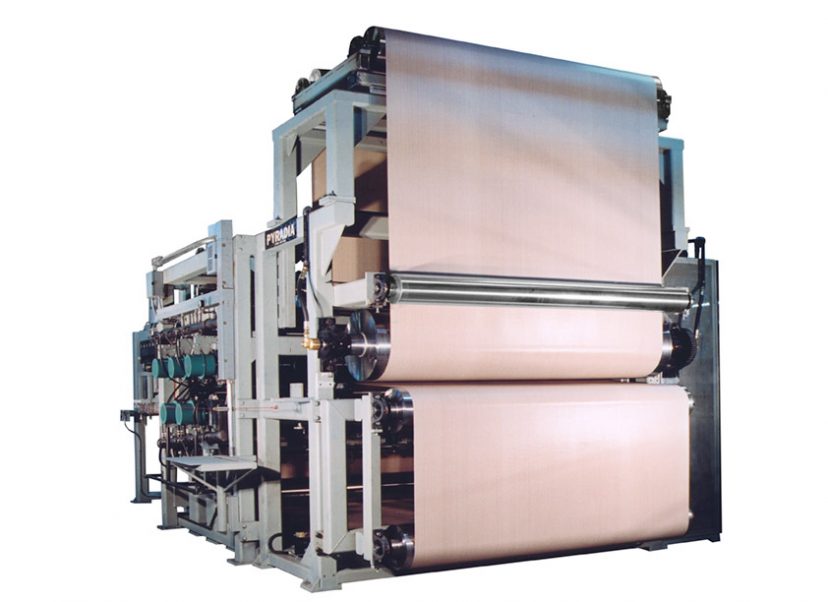

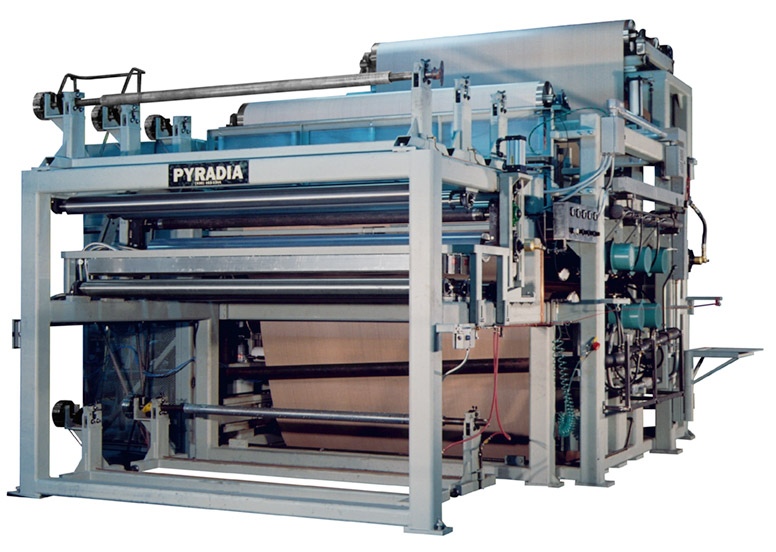

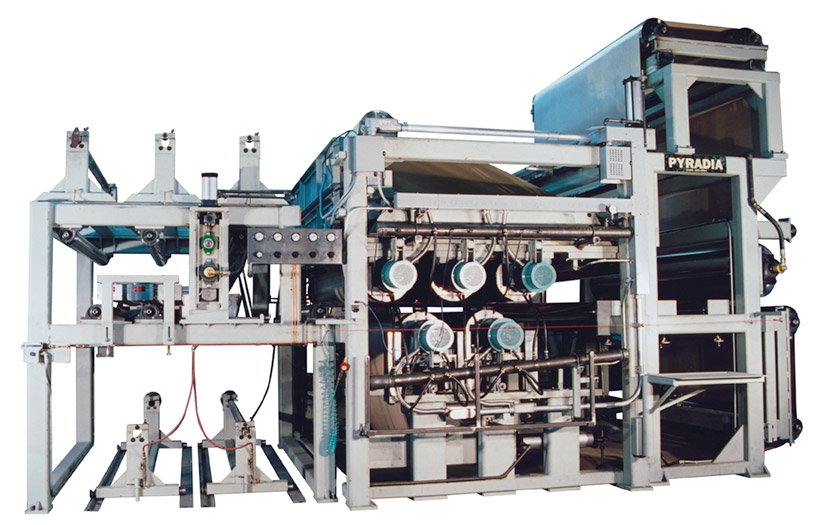

FLATBED LAMINATOR WITH DUAL STAINLESS STEEL BELT

Principles of operation of the dual stainless steel flatbed laminator:

• Belts pass through a multi-zone, open flame oven assuring even heat distribution with a high, efficient transfer rate.

• Belts are pressed against the material by the use of offset rolls throughout the forming and cooling process.

• A series of high pressure nip-rolls assures the desired compression and surface impregnation of the material.

• Belts and material are then cooled by water mists and air jets evenly and gradually distributed throughout the cooling chamber.

• Hot water is collected and cooled down in a water tower to be reintroduced into the cooling system.

Advantages over typical roller carpet/platen design:

• Up to 50% reduction of maintenance costs

• Up to 50% reduction of energy costs

• Significant reduction of acquisition costs

• Reduction of required floor space.

Typical specifications:

• Width : Up to 120 inches

• Line speed : Up to 35 fpm

• Material process temperature Up to 500°F

• Material exit temperature : As low as 100°F