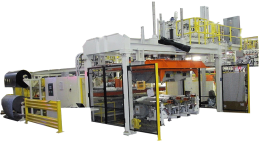

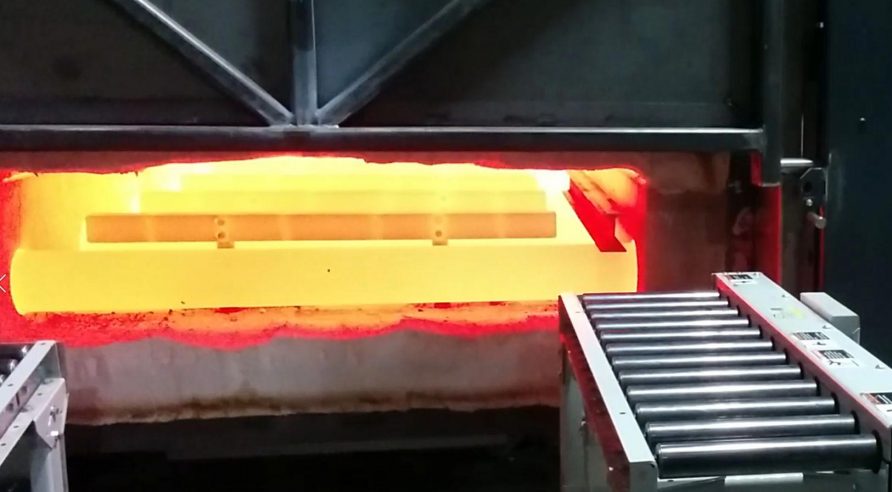

reliable and energy efficient heat treating solution

Details

TREATMENT PROCESSES

- Annealing

- Hardening

- Preheating

- Normalizing

- Stress Relieving

- Tempering

KEY FEATURES

- Large production

- High-level of uniformity

- Stable performances

- Low energy consumption

- Protective atmosphere

TYPES OF PARTS

- Tubing, bars and profiles

- Metal sheets

- Casting

- Forgings

- Coils