COATERS

COATERS

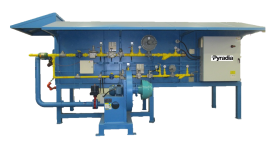

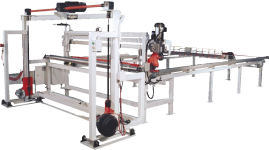

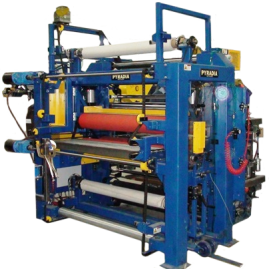

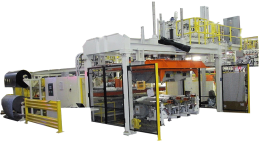

PYRADIA offers a complete line of coaters corresponding to your product characteristics. We manufacture the most flexible and reliable gravure, reverse gravure, reverse roll, knife over roll, saturation, cartridge and combination web coaters. All our coaters are designed according to the highest quality standards for long life and easy maintenance. The open frame design of our equipment makes PYRADIA’s web coating equipment the easiest to thread, clean and operate. We offer the choice of fabricated open frame design or heavy machined plate construction to better suit customer’s preferences or process needs.

With our roll-to-roll coaters you can use a wide range of viscosities. You have the choice of water base, 100 % solids or solvent base coatings. All our coaters are available with speed ranges that meet your requirements. Every web coater we manufacture can be added to an existing line or combined with PYRADIA’s unwinds, winders, laminators, calenders and dryers to create a completely new process line.

PYRADIA’s web coating equipment can be designed to provide different coating methods on the same machine. Each coater can be equipped with a PLC, a MMI and a computerized control system, depending of your specifications. PYRADIA’s roll-to-roll coaters are available in our standard range of characteristics, or specially designed for your particular application.

Type of equipment

Details

COATING METHODS

- Adhesive – Hot Melt – Pressure sensitive – PVC Resin

- Wear & Gloss Control – Polyethylene – Polyurethane – Acrylic Vinyl – Melamine Resin

- Silicone Release Liner

- Foam Block Out

- Humidity Barrier

- Structural – PVC – Epoxy

- Magnetic

- Special Process

COATING TECHNIQUES

SPECIAL WEB PROCESS EQUIPMENT

Special web process equipment is available and can be integrated to your process line to improve your production and reduce your set up time. In order to meet your specific requirements, PYRADIA offers a wide range of equipment for saturation and coating processes. Our coaters can be designed for papers, films, foils, textiles and composites applications.

FEATURES

- Enclosed doctor blade application

- Pan fed application

- Turret mounted backup rolls

- Automatic coating gap control

- Smoothing doctors

- Humidity control

| COATING MACHINE | Coating thickness (mils) | Viscosity (centipoise) | Speed Range (fpm) | Width (inches) |

| Knife Over Roll Coater(Kor) | 1 to 30 | 1,000 to 30,000 | 0 to 300 | 0 to 120 |

| Gravure Coater | 2 to 5 | 50 to 10,000 | 10 to 1200 | 0 to 80 |

| Offset Gravure Coater | 1 to 5 | 100 to 10,000 | 10 to 1000 | 0 to 80 |

| Reverse Roll Coater | 1 to 20 | 2,000 to 30,000 | 30 to 1200 | 0 to 100 |

| Multi- Roll Coater | 0.2 to 2 | 100 to 25,000 | 100 to 1200 | 0 to 80 |

| Slot Die Coater | 0.5 to 40 | 10 to 1,000,000 | 0 to 1200 | 0 to 80 |