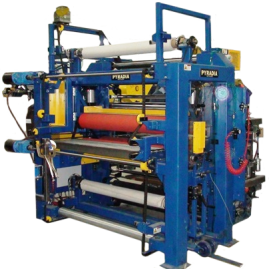

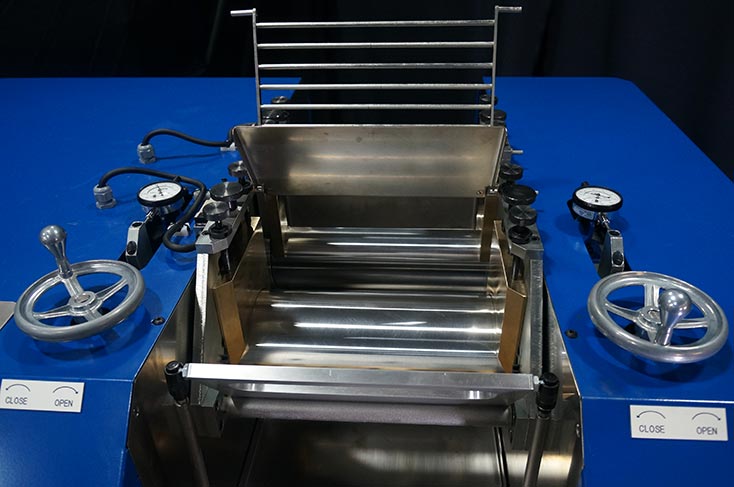

POLYMER & RUBBER BLENDING

Details

INDUSTRY: Polymer and rubber

APPLICATION: Heating and blending of various compounds

KEY SPECIFICATIONS:

- Dual Ø6” mixing rolls – electrically heated 6kW per roll

- Maximum temperature: 500°F +/-25°F surface uniformity

- Mixing roll face 12”

- Gap setting: 0.000” – 0.250” with micrometer adjustment

- Rolls are each independently driven by a 3HP motor & variable speed drive up to 50 FPM

- Total loading: up to 20,000 Lbs

- Easily removeable foot pedal operated bronze scrapper blade for mixed sheet removal

- Compact design with integrated fork truck lifting points