Wide range of viscosities

Details

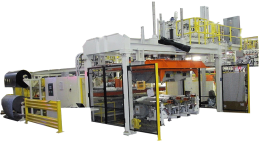

A FEW OF OUR PREVIOUS PROJECTS

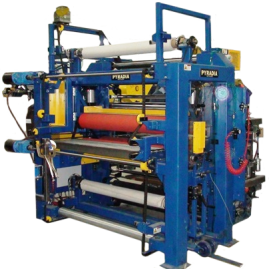

SINGLE SIDE GRAVURE COATER: This single side gravure coater (bottom side coating) was designed for a US automotive interior trim manufacturer to coat a 40″ to 80″ wide polyester foam web substrate.

OFFSET GRAVURE TOP COATER: The applicator and anilox rolls are driven by AC vector gear-motors and can turn in the forward or reverse direction.

Coating is furnished to the anilox roll through a chambered doctor system which also doctors the coating on the roll. The nip made between the applicator roll and anilox roll is manually adjustable by wedge blocks. The anilox roll is driven through a Schmidt coupling, which allows the nip to be adjusted and to be retracted 4” by pneumatic cylinder.

GRAVURE BOTTOM COATER: The bottom anilox roll, which is also the applicator roll, serves as the backup roll for the top coater.

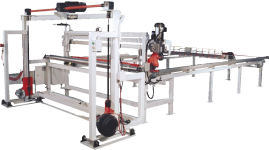

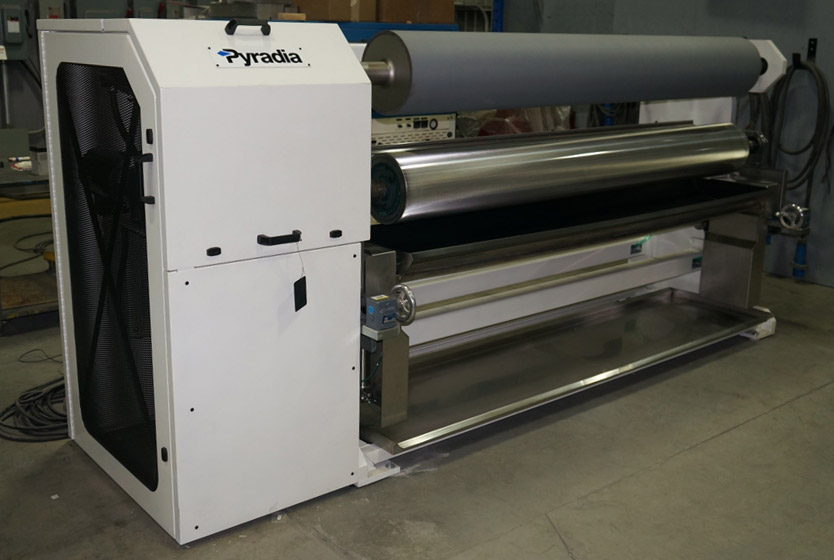

GRAVURE COATER WITH TURRET : This gravure coater offers forward & reverse operation and is equipped with an enclosed coating feed chamber. Three back-up rolls are mounted on a turret to allow for quick changeovers.

| COATING MACHINE | Coating thickness (mils) | Viscosity (centipoise) | Speed Range (fpm) | Width (inches) |

| Gravure Coater | 2 to 5 | 50 to 10,000 | 10 to 1200 | 12 to 80 |

| Offset Gravure Coater | 1 to 5 | 100 to 10,000 | 10 to 1000 | 12 to 80 |