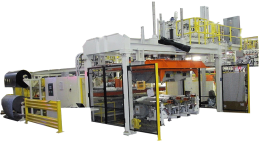

Quench transfer under atmosphere without loss of temperature

Details

Fields of application (under protective gas):

- Austenizing (hardening)

- Carburizing

- Carbonitriding

- Nitriding, nitrocarburizing, oxynitriding

- Annealing, tempering and brazing

- Treatments up to 2000°F (1100°C)

- Alkaline washing

- Solution heat treatment and ageing

- Washing with solvents

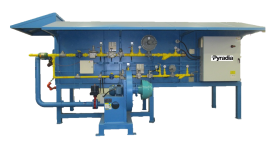

Quenching medium with suitable washing:

- Water

- Oil

- Molten salt

- Nitrogen

- Alkaline washing

- Washing with solvents

General specifications:

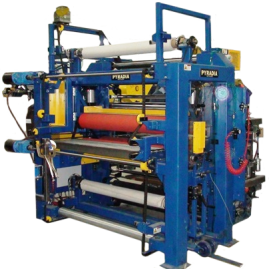

- Cylindrical stable chamber of long lifetime

- Turbine and guide cylinder for forced atmosphere convection, that means high uniformity of temperature ± 9°F (5°C) and carbon potential (± 0.05 % C)

- Easy access to the plug

- High speed cooling fan

- No thermal or mechanical shocks on the essential elements such as turbines & oxygen probes

- Gas injection without clogging

- Low maintenance

- Easy access to all elements

- Maximum working temperature: 1100°C

- Maximum gross load with loading fixtures: 5 tons

- Maximum useful load height: 4500 mm

Advantages of the installation:

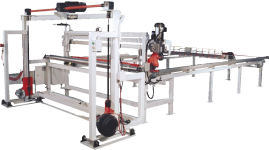

- Patented load transfer by gliding

- Without locking of the load

- Without mechanism, i.e. no breakdown

- Without any wear and locking elements

- Full gas protection during quenching

With this solution the quenching baths can be transferred to any heat treatment furnace. That means saving one or several baths. Considering the performance of these installations we dare say that the investment is paid off very quickly in comparison to other installations offered on the market.