THE BEST VOC DESTRUCTION SOLUTION

Details

PATENTED DESIGN

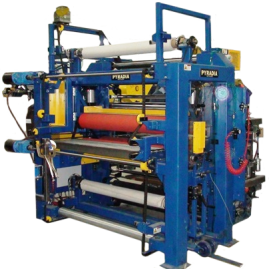

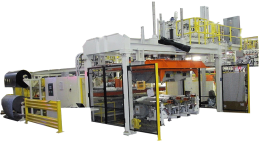

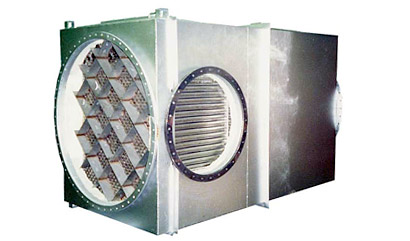

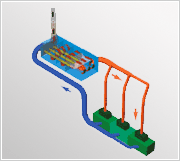

The illustration above shows how the VOC laden air is processed inside the thermal oxidizers. The contaminants are first preheated into a heat exchanger before being passed through a burner, where they are elevated to the appropriate destruction temperature. Once the proper temperature reached, the toxic and organic vapors are thermally converted to carbon dioxide and water vapors. The hot air is then returned to the heat exchanger and used to preheat the next contaminated airstream. Finally cleaned air is exchausted in the atmosphere.