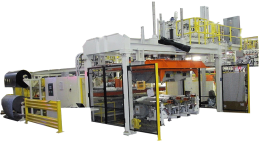

Pyradia was recently awarded a contract for an inert atmosphere annealing furnace from a major Canadian supplier to the energy sector. The main challenge with this project is that the unit will handle small fragile parts in a fully automated process.

The continuous conveyor oven will be used to heat treat spacer coil spring parts at 1650F under protective atmosphere. The parts will then be water quenched completing the heat treat process. The furnace will be equipped with proprietary high density vacuum formed heaters, Allen Bradley PLC and AB Panelview HMI pre-programme in-house.

Learn more about our industrial ovens & furnaces division and take a tour of our facilities. Follow us on Linkedin and Twitter!